Material is the material basis of all human production and life, has always been a sign of productivity, the ability to understand and use materials, determines the social form and people's quality of life。New materials are the cornerstone of the development of strategic emerging industries。

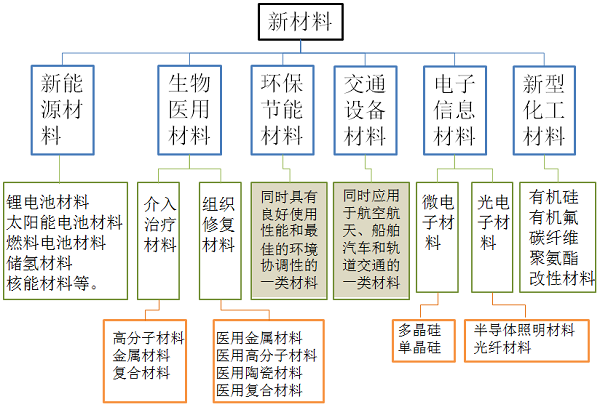

New material type

The present situation of China's new material industry

(一)

Production of new materials in China

Almost all new materials can be produced and are being produced in our country, including:

High performance engineering material

POK polyketone, PPO polyphenylene ether, PPS polyphenylene sulfide, polyether ether ketone (PEEK), polyether sulfone (PES), polycarbonate (PC), POM, polyimide (PI), PA(6, 66, 11, 1010, 56, 46, 12...)PMMA, PET, PBT.....

Electronic chemicals

Photoresist, conductive polymer materials, electronic packaging materials, electronic special gases, flat panel display (FPD) special chemicals, printed circuit board materials and supporting chemicals, chemicals for hybrid circuits, materials for capacitors, electrical coatings, conductive polymers and other electronic and electrical chemicals。

New elastomer

TPU, POE, SBS, SEBS, SEPS, TPEE, propenyl elastomer, nylon elastomer...(The total number of new elastomers is nearly half that of conventional elastomers.)。

New fiber

Spandex, aramid, ultra high molecular weight polyethylene fiber....。

(二)

Strong applications support the development of new materials in our country

Our country has huge industrial users;

A large shipbuilding country and a powerful country;

The world's largest producer of mobile phones;

The country with the largest automobile production and sales;

The country with the highest quality and quantity of subways, bullet trains and high-speed rail;

The world's largest producer of white electricity such as refrigerators and washing machines;

Therefore, strictly speaking, the strong downstream application industry has provided a huge driving force for the development of China's new material industry。

(三)

Policy promotes the development of new materials in our country

(1) The National Development and Reform Commission and the Ministry of Commerce issued the Catalogue of Industries to Encourage Foreign Investment (2019 Edition),The chemical raw materials and chemical products manufacturing industries highlighted include: differentiated, functional polyester (PET);Polyformaldehyde;Polyphenylene sulfide;Polyether ether ketone;Polyimide;Polysulfone;Polyether sulfone;Polyaryl ester (PAR);Polyphenyl ether;Polybutylene terephthalate (PBT);Polyamide (PA) and its modified materials;Liquid crystal polymer

(2) The National Development and Reform Commission's "Three-year Action Plan to Enhance the Core Competitiveness of the Manufacturing Industry (2018-2020)" key chemical new material key technology industrialization projects include: polyphenylene sulfide;Polyphenyl ether;Aromatic ketone polymers (polyether ether ketone, polyether ketone, polyether ketone ketone), polyether ether ether nitrile;Polybenzimidazole;Polyaramide;Polyaryl ether;Thermotropic liquid crystal polymer;New degradable plastics, etc。

(3) The "13th Five-Year" Development Planning Guide for the Petroleum and Chemical Industry of the China Petrochemical Association lists polymer materials as a strategic emerging industry as a priority area of development,It is clear that the purpose of the "thirteen-five" development of polymer materials is to improve the ability of independent innovation as the core,It focuses on the development of resin special materials, engineering plastics, new functional materials, high-performance structural materials and advanced composite materials,Development of engineering plastics, modified resins, high-end thermosetting resins and resin matrix composites,And biodegradable plastics and other new material preparation technology。

(4) The key work guidance of China Petroleum and Chemical Industry Federation on the "Strategy and Task for the Development of New Chemical Materials Industry in the 14th Five-Year Plan" : The development of resin materials (LCP, PI, epoxy resin, etc.) for core copper clad plates used in 5G communication base stations;Polysulfone, polyphenyl sulfone, polyether ether ketone, liquid crystal polymer and other high performance engineering plastics。

In addition, China's new materials industry related policy planning, also includes:

Made in China 2025;

The "New Materials Industry Development Guide" will indicate the key direction for the development of new materials industry during the "14th Five-Year Plan" period。

(四)

The application research and development system has become a powerful tool for the development of new materials

The application research and development system established in China for decades is profound, such as the Chinese Academy of Sciences, including the Beijing Chemical Institute, the Process Institute, the Ningbo Institute, the Shanghai Organic Institute, the Dahua Institute, the Lanhua Institute, the Ying chemical Institute, the coal chemical Institute...In addition, it has made an irreplaceable contribution to scientific and technological progress, economic and social development and national security。

Divided by materials, including the following mature R & D institution system:

In addition, there are a large number of R&D centers of large enterprises, and many of the research on product application and supporting testing instruments and equipment have reached the world's leading level。

(五)

The gap with foreign new materials

The gap between China's new materials industry and foreign countries is mainly in high-quality new materials。

China lacks advanced research and development advantages and practical development of research and development results, and is mainly based on imitation at present。Although many new materials have been able to produce, but the relevant patents can not be sidetracked。

Development trend of new material industry in China

Developed countries are fully developing new materials industry, such as the United States new materials called "scientific and technological development of the flesh", the development of new materials in China will also gradually transition from raw materials, basic chemical materials to emerging materials, semiconductor materials, new energy materials, energy-saving (lightweight) materials。

(一)

New material industry in the eyes of capital

1.100 billion tuyere

100 billion tuyere is mainly cost-effective, high-performance electronic chemicals, including chips, sensors, and semiconductor electronics (electronic adhesives, photoresist, conductive materials, high-purity gases, solvents, etc.)。

2.Trillion-scale tuyere

Trillion-level tuyere is mainly new energy-related materials, including solid state batteries, fuel cells, hydrogen fuel cells, lithium batteries, solar photovoltaic, renewable energy, energy storage, wind energy, etc。

3.Other tuyere

Other outlets include: biodegradable materials at an accelerated stage of development (conducive to garbage sorting, etc.), new materials for 3D printing, structured materials, and lightweight, energy-efficient materials。

(二)

Super money printing machine for new materials of the future?

Three hot spots in the new material industry

1

One of the three hot spots: Aramid, PI and PA

⏬ Aramid - a key strategic material

Aramid downstream applications high-end, is a key strategic material。

The characteristics of aramid products are high threshold, fewer domestic enterprises, obvious substitution trend of localization, and obvious upward trend of the industry at present。

The threshold of aramid products is mainly the technical and customer access threshold, to enter the market need to do safety certification, need several years of successful cases, downstream application field security requirements are very high。

目前全球的对位芳纶处于近平衡状态,国内对位芳纶80%依赖进口。From a global point of view, with the increase of application areas, the demand for para-aramid will gradually increase, and it is expected that the global demand for para-aramid will reach about 150,000 tons in the next five years。According to the annual growth rate of 10%, the demand for para-aramid in China will reach 13,000 tons in 2020, and the demand for para-aramid will reach 25,000 tons in 2025。

The global intermediate aramid industry is mainly occupied by companies such as DuPont, Taihe New Materials and Teijin of Japan。Among them, DuPont ranked first with 67% of production capacity, and Teijin accounted for 7%。

⏬ polyimide -- "Problem solver"

Polyimide is one of the organic polymer materials with the best comprehensive properties。Its high temperature resistance of more than 400℃, long-term use temperature range of -200 ~ 300℃, some no obvious melting point, high insulation performance, 103 Hz dielectric constant 4.0, dielectric loss is only 0.004~0.007, from F to H。

PI film

PI film is the earliest and most mature product in the PI series of products, and it is the best choice for insulating film, and the wave of localization of high-end products is approaching。

PI films below the electronic grade have achieved domestic self-sufficiency, and the PI film market above the electronic grade is still mainly divided by overseas companies。

With the gradual landing of domestic chemical imine production lines, domestic manufacturers will participate in sharing the high-end market of nearly 10 billion market。In the future, as the FCCL market maintains a high growth rate and the demand for flexible substrates increases with the rapid popularization of OLED, the high-end electronic grade PI film market will be in a period of rapid expansion。

PI fiber

Take root in the military market, and accelerate the development of the civilian market。PI fiber has excellent heat resistance and mechanical properties, and is the core accessory material in important fields such as aerospace and military aircraft, and its application in the military market is irreplaceable。

In the commercial field, PI fiber in environmental protection filter materials, fireproof materials and other applications are currently in the gestation period, the future is expected to add new vitality to PI fiber。

PI/PMI bubble

Benefit from the climax of warship construction, welcome the "blue ocean" era。At present, the most important application of PI foam is the heat insulation and noise reduction material for warships. At present, China's navy is in the third ship construction climax. PI foam is the preferred heat insulation and noise reduction material for new warships, and the future demand is expected to increase rapidly。In addition, as the most excellent structural foam core material, PMI foam is widely used in fan blades, helicopter blades, aerospace and other fields, and its replacement trend for PET foam is clear, and the market space is broad。

PI matrix composite material

Lightweight is the big trend, focusing on the high-end market。Fiber reinforced composite is a new generation of lightweight materials after magnesium aluminum alloy. Polyimide as a resin based composite has excellent high temperature resistance and tensile properties, and is widely used。With the gradual maturity of the carbon fiber industry, the demand for carbon fiber reinforced composite materials has increased significantly, and the combination of polyimide and carbon fiber, as one of the most excellent composite material combinations, has obvious advantages in seizing the high-end market。

PSPI(Photosensitive polyimide)

Photoresist, electronic packaging dual fields of strength, enjoy the high-end dividends of electronic products。Photosensitive polyimides have two main applications: photoresist and electronic packaging。Compared with traditional photoresist, PSPI photoresist does not need to be coated with light blocking agent, and can greatly reduce the processing process。PSPI is also an important electronic packaging adhesive。

Photosensitive polyimide as a packaging material can be used in: buffer coating, passivation layer, alpha ray shielding material, interlayer insulation material, chip packaging material, etc., but also widely used in the microelectronics industry, including integrated circuits and multi-chip packaging packages。

⏬ 尼龙

High temperature resistant nylon

The technical barriers to high temperature nylon are relatively high, the industry has not been large-scale development, and there is a huge gap in market demand。The research of high temperature resistant nylon in China is relatively late, and the development of new varieties is mainly based on the modification of PA6T, supplemented by the synthesis of new nylon。

High temperature nylon as a high-performance engineering material market continues to expand, it is expected that China in the next few years, the demand for high temperature nylon will grow at a rate of 15% to 25%。

The potential demand for high temperature resistant nylon accounts for 20-30% of nylon, and the demand for nylon in the Chinese market is expected to reach 10,000 tons within five years。

Nylon elastomer

Nylon elastomers are polyester/polyether-polyamide block copolymers, the most common is polyether block amide (PEBA), which is more prominent properties are high resilience, light weight and low temperature impact resistance。

The energy feedback of nylon elastomer can reach 85%, which is about 15% higher than Boost cushioning technology, and has a better shock absorption buffer effect。Compared to TPU, it is lighter in weight。

Nylon elastomer synthesis technology threshold is high, mostly in the hands of French Arkema, Germany Evonik, Japan Ube Xingko and other foreign manufacturers。

Nylon elastomer market demand potential is huge, in addition to 44 billion pairs of shoes/year substrate demand, as well as the replacement of polyurethane soft foam, plastic runway materials。

Three hot spots second: electronic chemicals

Electronic chemicals are fine chemical materials specially designed for the development, etching, cleaning and electroplating processes in the manufacture of electronic information products, and are important supporting materials for the information industry such as integrated circuits and flat panel display manufacturing。

2017年,世界Electronic chemicals产值>1500亿美元,中国产值约2600亿元,预计2018-2022年,年均增长率约为11%。Companies including Dow, Honeywell, Mitsubishi Chemical and BASF are racing to focus their electronic chemicals business on the Asia-Pacific region, including China。China's abundant raw materials and proximity to downstream demand are obvious advantages, and the transfer of electronic chemical production capacity to the domestic has become the general trend。

Three hot spots: lightweight, energy-saving materials

The key to lightweight - high-performance new materials such as TPEE, POM, PI, PA, PU, TEEK, PPA, PTT and so on to replace the proportion of steel several times。

Polymer curing technology - A research team led by Professor ScottWhite at the University of Illinois has developed a new polymer curing technology,A small heat source is needed for polymer fabrication in a short time,Compared to current manufacturing processes,Reduces energy consumption by 10 orders of magnitude,And reduce man-hours by two orders of magnitude。

Carbon fiber - lightweight while pursuing high performance。

The four major materials of the new materials industry

2

One of the four major materials: film

Material film market

China's material film industry growth is stable, 2010-2017 China's material film production increased from 7.99 million tons to 15.7 million tons, the average annual compound growth rate of 10%。

In 2017, the global sales volume of liquid crystal polymer films and laminates was about 9,050 tons, with a compound annual growth rate of 6.7%。

Express packaging film will show a reduction, green, recyclable development trend。

The optical film of the backlight module will tend to be high brightness, thin shape, light weight and high color gamut。

Optical polyester film industry

The preparation technology of functional polyester raw materials is one of the core technologies of film making enterprises, among which nano-micron addition modification, involving smooth uniformity, crystallization uniformity and static voltage film property, is the technical bottleneck that hinders the development of the industry。

At present, the domestic optical polyester film industry is still in the initial stage, most of them focus on the film stretching processing, lack of systematic research on optical polyester film technology。

It is difficult to compete with international giants in terms of optical polyester film materials (special slices and masterbatch), formula design, equipment and process control, which restrict the development of new display industries in China;Third, the overall scientific and technological innovation of the industry lacks coordination and linkage。

BOPA film industry

BOPA film is mainly used in food, daily chemical, medicine, electronics, construction, machinery and other packaging fields, of which food packaging accounts for 70%-80% of the share, mainly for high temperature cooking, freezing, leisure food。

It is expected that in the next few years, China's flexible packaging and BOPA film market will continue to show growth, and overseas markets will become another new growth point。

BOPET film industry

Because of its excellent physical and chemical properties and environmental protection properties, BOPET film is known as one of the most promising new materials in the 21st century。

China's BOPET polyester film demand accounts for 33% of the total global demand。

Downstream application industries are mainly packaging materials, electronic information, electrical insulation, card, image film, hot stamping foil, solar energy applications, optics, aviation, construction, agriculture and other production fields。

At present, the largest application field of mylar film produced by domestic manufacturers is the packaging industry, such as food and beverage packaging, pharmaceutical packaging, and some special functional mylar film is used in high-end fields such as electronic components and electrical insulation。

BOPP film industry

BOPP film has the reputation of "packaging queen", and the apparent consumption of BOPP film in China was 251 in 2013.In 2017, it has reached 3.3 million tons, an increase of 32% in 5 years。

With the continuous improvement of China's consumption level and the rapid development of post-processing color printing composite, composite film, aluminum plating, coating and other industries, the demand for BOPP film has great market potential。

BOPE film industry

BOPE film industry will become a film industry focus, which has the following advantages:

More suitable for mass order production needs;

High transparency, high gloss, few crystal points;

High stiffness, high tensile strength;

High puncture resistance;

Excellent low temperature impact strength and pinhole resistance, wear resistance, excellent low temperature flexibility;

Long wetting tension holding time, good printing performance, accurate overprinting。

Using half thickness of BOPE instead of blowing material or casting CPE film and BOPA or BOPET dry composite can achieve the same heat sealing strength and close stiffness;

In addition, half of the thickness of BOPE instead of blowing material or casting CPE film and BOPA dry composite for frozen packaging can greatly reduce the broken bag rate。

Two of the four materials: 3D printing materials

At present, the commonly used 3D printing polymer materials are polyamide, polyester, polycarbonate, polyethylene, polypropylene and ABS。Although the most common market materials for 3D printing are ABS and PLA, nylon is actually the largest material used。Nylon is expected to account for 30% of the 3D printing materials market by 2022。

The main factors affecting the application of materials in 3D printing are: high printing temperature and poor material fluidity,Volatile components appear in the working environment,Print nozzle easily blocked,Affect product precision;Ordinary materials have lower strength,The scope of adaptation is too narrow,The material needs to be enhanced;The cooling uniformity is poor,Slow setting,Easy to cause shrinkage and deformation of products;Lack of functional and intelligent applications。

Global 3D Printing Market ($100 million)

Application field analysis

The future large-scale industrial applications in the global 3D printing market is expected to usher in explosive growth。

In the industrial field, 3D printing has formed a complete industrial chain after 30 years of development。

At present, 3D printing technology has been applied in the military, aerospace, medical, automotive, mechanical equipment manufacturing and consumer fields。

3D printing is used in construction, building load-bearing parts, automotive parts, industrial parts。Every link of the industrial chain gathers a group of leading enterprises。

Development direction of 3D printing materials in China

With the development of 3D printing technology, the performance of traditional materials has been greatly improved, relying on the strong rapid melting deposition and low temperature bonding characteristics of materials will be widely used in the field of 3D printing manufacturing。In addition to the material itself can be 3D printed products, 3D printing in glass, ceramics, inorganic powder, metal, etc., needs to rely on the adhesion of the material to complete。

The strength of the modified material is used to directly replace the metal for various complex components, which is cheap and lightweight。It can even replace glass, ceramics and other products, so that the material is widely used in 3D manufacturing。

Materials can avoid the defects of low strength, and develop towards composite and functional, especially to achieve multi-material composite, thus giving materials specific functions。New materials such as smart materials, photoelectric polymer materials, photothermal polymer materials, photovoltaic polymer materials and energy storage polymer materials are manufactured by 3D printing technology。

3D printing has the advantages of rapid repair without molds and parts, which can advance China's manufacturing industry for 5-10 years, and 3D printing is a revolution in the industry。

Three of the four materials: degradable materials

Biodegradable materials subdivision applications (10,000 tons)

It is expected that by 2020, China's production of biodegradable materials will reach 2.5 million tons。The "13th Five-Year Plan", the international total carbon law, and the improvement of the performance and price of biodegradable materials will bring unprecedented development opportunities for China's biodegradable materials industry。

The complete biodegradable materials mainly include PLA, PHA, PBS/PBSA, PCL, PVA, PPE/PPC/PPB and a small part of PSM。Biodestructive materials mainly refer to the modification of traditional polyolefin by biodegradable resins, and most of PSM belongs to this category。

The development of biodegradable materials is more and more in line with the environmental protection concept of society, the current global research and development of biodegradable materials up to dozens of varieties, but to achieve batch and industrial production only PSM, PLA, PBS/PBSA, PHA, PCL and so on。

2015-2020 Global demand forecast for three major biodegradable materials

Four materials: New elastomers

Acrylyl elastomer

Allylene-based elastomer is produced by the combination of metallocene catalytic technology and solution polymerization process. It is a unique semi-crystalline copolymer of allylen-ethylene, which has unique high elasticity, flexibility and low temperature impact resistance, especially excellent compatibility with PP。

Currently, only three companies in the world have commercialized allylene-based elastomers: Dow's versify, ExxonMobil's vistamaxx, and Mitsui's tafmer。

Advantages of propylene elastomer:

Allylene-based elastomers have the characteristics of good feel, high filling, and good anti-slip, such as the foaming advantage of ExxonMobil vistamaxx;

VM foaming products have good hand feel, good density, and a gummy feeling;

With high filling, the filling amount can reach 100phr, and the filling amount of EVA is generally 30phr, which has great advantages in reducing costs and doing some functional materials, such as flame retardant materials, which rely on filling to play the performance;

It can be 100% recycled, and the foam out of the product will not appear the distribution of pores on the surface of the product is not good, and EVA foam if you add too much recycled material (generally add 30phr), there will be a bad density distribution phenomenon;

Using VM to do some relatively low hardness foaming process is much easier to operate than EVA。If the hardness of EVA is 10°C, it is very difficult, and SEBS is generally added to increase the softness, and VM is easy to do;

Improved impact strength opens up opportunities for thinning, reducing material use and reducing costs;

The acrylic elastomer has a lower melting temperature, which reduces the processing temperature, and its higher flow rate will increase the processing speed。This can reduce energy consumption and improve processing efficiency。Its flexibility helps to improve the draw ratio and reduce flow marks, resulting in better product quality and lower scrap rates。Because the shrinkage rate of this elastomer is lower than that of polypropylene, the production process is easier to control and the die cutting is more accurate, which improves the match between the cup and the lid and helps to reduce the scrap rate。

Application of propylene based elastomers:

Random copolypolypropylene (RCP) is widely used in food preservation box, but the problem of low temperature impact resistance is common。The application of propylene based elastomer to polypropylene modification can improve the toughness of polypropylene。As a toughening agent in RCP, it can improve the toughness while maintaining the transparency of RCP, and help to reduce the stress whitening of hinge structure.

The blending of propylene based elastomers with polypropylene (PP) can achieve a better balance of impact resistance, transparency and stiffness, while improving processing efficiency;

Can be used in non-woven fabric, elastic film, polymer modification, etc., of which polymer modification performance is excellent, the specific application cases are washing machine seat, food container cover, humidifier water tank, plastic stationery, sports kettle, slippers and so on。

Vinyl elastomer

Properties and characteristics of vinyl elastomers:

The crystalline zone of polyethylene chain (resin phase) acts as the physical cross-linking point,It has typical plastic properties,After adding a certain amount of α-olefin (1-butene, 1-hexene, 1-octene, etc.),The crystallization zone of the polyethylene chain is weakened,Formed an amorphous zone (rubber phase) showing rubber elasticity,So that the product has the properties of elastomer;POE has the dual characteristics of plastic and rubber with excellent comprehensive performance,Therefore, POE can be regarded as a bridge product of plastic and rubber。

POE elastomers compared to EPDM,It has the advantages of excellent weld strength, good dispersion, high impact strength and excellent molding ability.Compared to SBR,It has the advantages of good weather resistance, high transparency, low price and low density.Compared to EVA, EMA and EEA,It has the advantages of small density, high transparency, good toughness, good flexibility, etc.Compared with soft PVC,It has the characteristics of no special equipment, low corrosion to equipment, good thermoforming, good plasticity, low density, good low temperature brittleness and good economy。

As a plastic toughening agent, POE elastomer can not only toughen and modify polyolefin plastics compatible with it, but also effectively graft with maleic anhydride, glycidyl acrylate and other monomers by peroxides. The grafts obtained are widely used to toughen nylon, polyester and other engineering plastics。

Polyolefin elastomer POE molecular structure has no unsaturated double bond, has a very narrow molecular weight distribution and short branch chain structure (short branch chain distribution uniform), so it has high elasticity, high strength, high elongation and other excellent physical and mechanical properties and excellent low temperature resistance。

The narrow molecular weight distribution makes the material not flexure during injection and extrusion processing, so the processing performance of POE material is excellent。Due to the saturated structure of the POE macromolecular chain, the molecular structure contains relatively few tertiary carbon atoms, so it has excellent heat aging and ultraviolet resistance。In addition, the long branched chain is effectively introduced into the branched structure of the linear short branched chain of the polymer, which improves the transparency of the material and effectively improves the processing rheology of the polymer。

Applications of vinyl elastomers:

POE can threaten rubber, flexible PVC, EPDM, EPR, EMA, EVA, TPV, SBC and LDPE materials;

Used in different products, such as automotive baffles, flexible conduits, conveyor belts, printing rollers, sports shoes, wire and cable, automotive parts, durable goods, extruded parts, press molds, sealing materials, pipe fittings and fabric coatings, etc.

It can also be used as a low temperature impact modifier to improve the low temperature impact resistance of PP, and can be used as a thermoplastic elastomer in the automotive field。

How much elastomer is vinyl and propylene?

The foreign dependence of China's natural rubber has exceeded 85%;

More than 44 million tons/year of new ethylene capacity is being built with vinyl elastomers as a potentially good downstream;

More than 40 million tons/year of new propylene capacity is being built with this potentially good downstream of propene-based elastomers!

Vinyl, propylene elastomers - related technology development is imminent!

Fluorine/silicon elastomer

Fluorine silicone rubber is composed of fluorine silicon polymer as the main formula, fluorine silicon polymer main chain contains a number of silicone groups (-SI-O -), its non-toxic, high and low temperature resistance!Can be made into thermoplastic elastomer。

Fluororubber - "the king of rubber" : has a high degree of chemical stability, is currently the best of all elastomers;Excellent high temperature resistance, excellent weather aging resistance and ozone resistance, vacuum performance and excellent mechanical properties, etc. - excellent comprehensive performance of elastomer varieties。Several small shortcomings: such as low temperature performance is not good, radiation resistance is also poor。

Five focuses of the new material industry

3

One of the five focuses: Structured materials

With tailor-made material properties and responses, lightweight using structured materials can improve energy efficiency, payload capacity and lifecycle performance, as well as quality of life。

Future research directions include developing robust methods for decoupling and independently optimizing properties, creating structured multi-material systems, and more。

We do not want the new material to be understood at the chemical level, but should maximize its use at the physical property level。

Two of the five focuses: Energy materials

Research and development directions include:

Continuous research and development of amorphous silicon, organic photovoltaic, perovskite materials and other solar energy conversion materials into electricity, development of new luminous materials, research and development of low-power electronic devices, development of new materials for resistance switching to promote the development of neuromorphic computing。

Researchers at Okayama University in Japan have recently developed a new type of solar cell made from a compound of iron oxide。The solar cell's light absorption rate is more than 100 times that of previous silicone solar cells。

Research direction of catalytic materials:

Theoretical prediction of improved catalytic materials, synthesis of inorganic core/shell nanoparticles with high catalytic performance, scalable synthesis schemes of efficient catalysts suitable for industrial production and applications, selective deposition of cocatalysts on active sites in catalytic reactions, research on two-dimensional materials catalysts。

Five focuses three: Extreme environmental materials

Extreme environment materials refer to high-performance materials that can operate in a variety of extreme operating environments。

Research interests include:

Science-based design to develop the next generation of materials for extreme environments, such as using understanding of temperature-dependent nanoscale deformation mechanisms in materials to improve alloy design, and using scientific understanding of corrosion mechanisms to design new corrosion-resistant materials;

Understand material performance limits and basic degradation mechanisms under extreme conditions。

Five focuses four: Materials for carbon capture and storage

Materials for carbon capture and storage include: carbon capture based on solvents, adsorbents and membrane materials, novel carbon capture materials such as metal-organic frameworks, electrochemical capture, and carbon storage through geological materials。

The material problem of clean water involves the interfacial material science phenomena in membranes, adsorbents, catalysts and underground geological structures, requiring the development of new materials, new characterization methods and new interfacial chemicals。

Research on materials for renewable energy storage is based on:

Research and development of multivalent ion conductors and new battery materials to increase the energy density of lithium-ion batteries, and research and development of new materials for high energy density hydrogen storage to achieve water decomposition/fuel cell energy systems。

Five focuses: Nanomaterials

Nanomaterials are materials that have at least one dimension in the nanoscale range (1-100nm) or are composed of them as basic units in three-dimensional space, which is equivalent to a scale of about 10 to 100 atoms tightly packed together。

Due to the small size effect, surface effect, quantum size effect and macroscopic quantum tunneling effect of nanoparticles, they show the characteristics of magnetic, optical, electrical, sensitive and other aspects that conventional materials do not have。Therefore, nano-particles have broad application prospects in magnetic materials, electronic materials, optical materials, high density materials sintering, catalysis, sensing, ceramic toughening and so on。

Two-dimensional and three-dimensional nanomaterials - electrode materials, electrochemical energy storage。

China's new material industry development suggestions

The proportion of chemical enterprise types in Europe, America and China

1= fine chemical and new material type multi-chemical enterprises

2= traditional petrochemical oil and gas and basic chemical enterprises

3= other types of enterprises

At present, China's traditional petrochemical oil and gas and basic chemical enterprises, huge investment is in full swing, there are several hundreds of billions of investment projects cluster, billions of investment projects have been "countless".。But earnings are falling sharply, and more and more basic chemical products, such as TDI, ethylene glycol, methanol, MMA market prices have plummeted;Even PC, PMMA and PA66, which still rely on imports, are no exception。

Therefore, we must pay enough attention to the development of new materials industry, otherwise, the real economy will not have a strong competitiveness!

First of all, industrial consumer enterprises should promote the development of China chemical new materials, their participation and support is key。

Rail transit (high-speed rail, bullet train, subway) - almost all produced by CRRC Group;

CSSC monopolizes China's shipbuilding industry-the world's top three;

Gree, Midea, Haier, etc. are world-class home appliance giants;

The world's largest automobile manufacturing industry;

The world's largest consumer electronic products (mobile phones, pads, computers) production base, consumer market;

There are blue moon, white and other Japanese big man。

Secondly, through the understanding of application - to promote the development of new chemical materials

Organofluorine material

A hydrocarbon containing fluorine

Organosilicon material

High and low temperature resistance, electrical insulation, weather resistance (light, radioactivity, ozone), non-toxic, flame retardant, antioxidant and other excellent properties

Engineering, modified materials

Industrial materials used as industrial parts or housing materials。

High performance fibre

Carbon fiber, aramid fiber, ultra high molecular weight polyethylene fiber

Electronic chemical materials - Materials used in the three major product areas of microelectronics, optoelectronic technology and new components, mainly including:

Semiconductor microelectronics materials represented by monocrystalline silicon;

Photoelectronic materials represented by laser crystals;

Electronic ceramic materials represented by dielectric ceramics and thermal ceramics;

Ndfeb permanent magnet material as the representative of the magnetic material;

Optical fiber communication materials;

Magnetic storage and optical disk storage based data storage materials;

Piezoelectric crystals and thin film materials;

Green battery materials represented by hydrogen storage materials and lithium ion embedding materials, etc。